Introduction: When "Kerbside Delivery" Isn't an Option

In the world of timber construction, standard logistical challenges usually involve narrow driveways or low-hanging trees. But what happens when the building site has no road access at all? What happens when the only route to the foundation is via a tidal river on the Norfolk Broads?

At Timber Building Specialists, we do not shy away from the impossible. In fact, we define ourselves by our ability to deliver premium, bespoke log cabins to the most demanding locations in the UK. We are not just a supplier of wood; we are logistical engineers and architectural partners.

Our recent project for the East Anglian Cruising Club (EACC) serves as the ultimate case study for our capabilities. This was not merely a shed installation; it was the construction of a 32sqm commercial-grade clubhouse, fully insulated and engineered for year-round use, delivered entirely by boat.

This comprehensive guide details every step of the process—from the planning hurdles and grant funding to the riverside foundations and the unique "flotilla" delivery system. It stands as a testament to why Timber Building Specialists is the UK’s leading log cabin company for bespoke, commercial, and challenging residential projects.

1. The Timber Building Specialists Difference

Before diving into the specifics of the EACC build, it is crucial to understand why this project was entrusted to us. In a market flooded with budget "off-the-shelf" garden rooms, Timber Building Specialists stands apart.

1.1 Beyond the Catalogue

While we offer a stunning range of Garden Log Cabins, our core expertise lies in modification and bespoke design. The EACC required a specific footprint to meet strict Broads Authority planning permissions. A standard 4x4m cabin wouldn't suffice; they needed a tailored 7.05m x 4.55m structure. We engineered this specific size without compromising structural integrity.

1.2 Commercial Grade Materials

A clubhouse used by 60+ members is not a summerhouse. It undergoes high foot traffic, door slamming, and exposure to harsh riverside elements (wind, moisture, and salt air). We utilised 68mm solid wall logs and Superior Grade Double Glazing. Most competitors cap out at 44mm logs for similar sizes. Our commitment to thicker timber ensures our buildings last for decades, not just seasons.

1.3 The "Can-Do" Installation Team

The primary reason clients choose us for complex builds is our installation team. Many suppliers strictly offer "kerbside delivery." If we had offered that to the EACC, their clubhouse would still be sitting in a car park two miles away. We worked directly with the club to facilitate a manual offload onto safety boats—a level of service few others in the UK would entertain.

2. Project Background: The EACC's Vision

The East Anglian Cruising Club, a historic institution on the Norfolk Broads, needed a heart for their community. Their existing facilities—a small shed and storage box—were no longer fit for purpose. They envisioned a proper clubhouse: a place for shelter during regattas, a venue for social evenings ("sing-songs"), and a secure location for club assets.

2.1 The Site Challenges

The proposed site was idyllic but logistically nightmarish for heavy construction:

-

No Road Access: The site is accessible only by footpaths or the river.

-

Flood Risk: Being riverside, the ground is marshy and prone to waterlogging.

-

Planning Constraints: The Broads Authority has strict rules on the aesthetics and size of structures to preserve natural beauty.

2.2 Funding and Grants

This project also highlights the financial viability of our cabins for community groups. The total build cost was approximately £40,000. Impressively, the club secured a UK Shared Prosperity Fund capital grant from the North Norfolk District Council (NNDC), covering 75% of the costs (£30,000).

For other clubs reading this: Timber Building Specialists can provide the detailed technical drawings and fixed-price quotations required to secure such government funding.

3. The Bespoke Specification: Evolution of the "Phil 68"

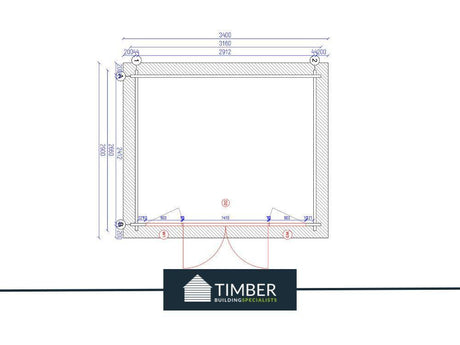

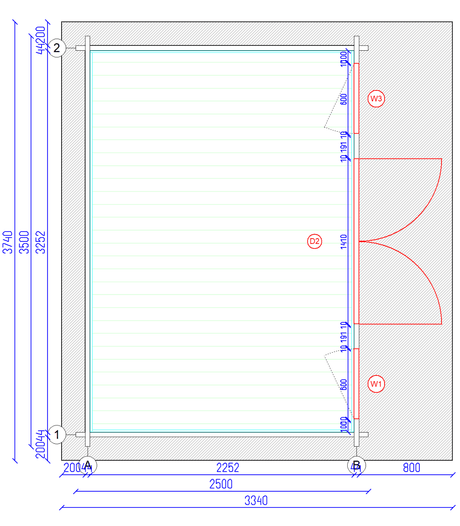

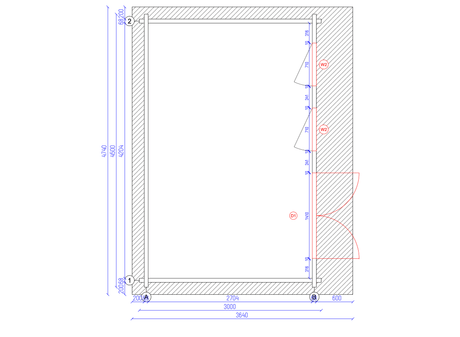

To meet the variation in planning permission (which required a reduction in internal floor area from 40sqm to 30sqm), we adapted our popular "Phil" model.

3.1 Structural Specifications

-

Model Base: Bespoke Log Cabin (Modified Phil 68 style).

-

External Dimensions: 7.05m x 4.55m.

-

Internal Area: Approx 30sqm (The "sweet spot" for planning compliance in this specific case).

-

Wall Logs: 68mm Solid Spruce. This is a critical specification. A 68mm log offers substantial "thermal mass," meaning the walls absorb heat during the day and release it slowly at night. For a clubhouse without central heating, this natural regulation is vital.

-

Floor: 28mm Tongue and Groove Boards. Standard cabins use 19mm. We upgraded to 28mm to support the weight of 60 people during social events.

-

Roof: Heavy-duty purlins designed to support corrugated metal sheets (essential for the exposed location).

3.2 Glazing and Security

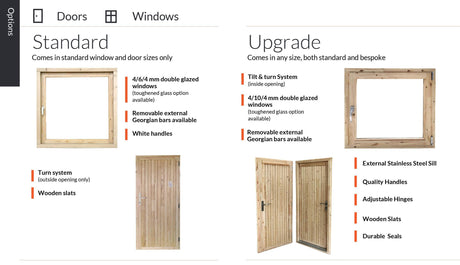

Security was paramount for a remote building. We installed our Superior Grade Windows and Doors:

-

Double Glazing: 3mm glass / 12mm air gap / 3mm glass.

-

Mechanism: Tilt and Turn (allowing ventilation without opening the full window).

-

Mullions: Decorative timber bars to maintain the traditional "Broads" aesthetic.

4. Phase 1: The Foundation Strategy

Before a single log could be delivered, the ground needed preparation. You cannot pour a concrete slab on a marshy riverbank without immense cost and environmental damage.

4.1 The Telegraph Pole Solution

The club opted for a genius, low-impact foundation solution suitable for wetlands.

-

Piling: Telegraph poles were driven deep into the ground to find stable soil.

-

Ring Beam: A heavy timber frame (ring beam) was constructed to sit on top of these poles.

-

Elevation: This raised the entire cabin approximately 100mm off the ground.

Why this matters:

-

Flood Protection: If the river rises, the cabin remains dry.

-

Airflow: Air circulates beneath the cabin, preventing rot in the floor joists—a critical consideration for any Log Cabin Maintenance.

-

Levelling: The poles allowed for a perfectly level platform on uneven terrain. If the base isn't level, the interlocking logs won't seat correctly.

5. Phase 2: The Nautical Delivery

This is the phase that defines the project. Usually, our fleet of trucks delivers to a driveway. Here, the "driveway" was the River Thurne.

5.1 The Staging Ground

We delivered the massive packs of 68mm timber, windows, doors, and roofing materials to a local staithe (a landing stage) accessible by road. This required precise timing to meet the club's volunteer work party.

5.2 The "Flotilla"

The EACC mobilised a fleet of safety boats. Our team and the club members broke down the heavy pallets into manageable loads.

-

Manual Handling: Every single wall log was hand-lifted onto a boat.

-

Balance & Safety: Transporting long timber lengths on small boats requires care to maintain stability.

-

The Shuttle Run: The boats made multiple trips downriver to the mooring site.

This operation proves the versatility of log cabin construction. Unlike brick and mortar or steel, timber is modular. It can be carried piece by piece to mountainsides, islands, or, in this case, a riverbank.

6. Phase 3: The Build Process

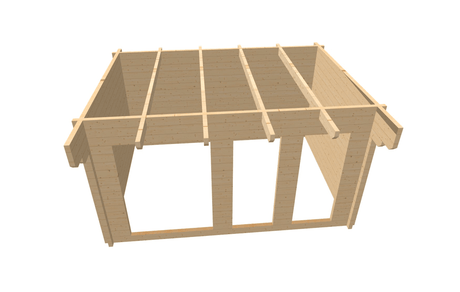

With the materials finally on site, the Timber Building Specialists installation team took over. This is where professional installation pays for itself.

6.1 The Shell Erection

Log cabins rely on precise interlocking corners.

-

Day 1-2: Our team laid the base logs onto the ring beam and began stacking the 68mm walls. Using rubber mallets and tapping blocks, the logs were driven tight to ensure an airtight seal.

-

The Ring Beam Check: We ensured the cabin was perfectly square on the club’s telegraph pole base. A discrepancy of even 10mm at the bottom can result in a roof that doesn't fit.

6.2 Roofing and Watertight Status

By October, the weather in Norfolk can turn wet. Our priority was getting the purlins and roof boards on.

-

Speed: Within a few days, the structure was "watertight."

-

Corrugated Roofing: The club opted for metal corrugated sheets over the top of our timber roof boards. This provides the ultimate protection against driving rain and is low maintenance compared to felt.

6.3 Windows and Doors

The "Superior" double doors and windows were fitted. Importantly, we allow for "expansion gaps" above the doors and windows. Timber breathes—it expands in winter (absorbing moisture) and contracts in summer. If windows are screwed too tightly to the logs, the cabin can't settle. Our installers ensure these engineering tolerances are perfect.

7. Phase 4: Finishing Touches (The Community Effort)

One of the great aspects of our service is that we can provide the "shell" (the difficult structural work), allowing the customer to handle the finishing touches to save money or, in this case, to foster community spirit.

Once Timber Building Specialists handed over the watertight structure, the EACC volunteers took over:

7.1 Cladding and Insulation

While the 68mm logs are highly insulating, the club added additional cladding in certain areas for aesthetic continuity with local architecture.

7.2 The Decking

A wrap-around deck was constructed to connect the clubhouse to the riverfront. This provides a "regatta watching" platform.

-

Material: Pressure-treated timber decking.

-

Design: Integrated with the cabin's floor height for seamless indoor-outdoor flow.

7.3 Painting and Preserving

Treating a log cabin is mandatory. The club chose a crisp white paint for the window and door trims (RAL 9010 style) and a high-quality preservative for the logs.

-

Recommendation: We always recommend a high-grade treatment like Cuprinol or Sadolin to protect against UV rays and fungal decay.

7.4 Interior Fit-Out

The interior was finished with a laminate floor over our 28mm boards. This is a smart choice for a clubhouse; muddy sailing boots can be wiped clean easily.